Stationary Crushing Plant

Overview

Gilyoung SNC’s stationary Jaw crusher is widely used for crushing all kinds of minerals and rocks, it has a compact but strong and firm construction which offered trouble-free operation and easy maintenance.The replacement component and jaw plate’s are composed of abrasion and strong durability material, be easily able to transportation and easily disassembly and assembly for easy field operation.

The secondary crusher and tertiary crusher is composed the new development MC series. We are able to efficient and economical engineering with have the variety models from small to large. And compared to same level of model,the production volume is increased for 16% or more.

For the qualitative improvement process capability and facility convenience apply of topseal fixed method using lockpost cylinder, and attachment of the hydraulic cylinder is able to easy treatment of blockage of the crushing chamber.

-

50T/HR Crushing Plant

50T/HR Crushing Plant

-

100T/HR Crushing Plant

100T/HR Crushing Plant

-

150T/HR Crushing Plant

150T/HR Crushing Plant

-

200T/HR Crushing Plant

200T/HR Crushing Plant

-

300T/HR Crushing Plant

300T/HR Crushing Plant

-

600T/HR Crushing Plant

600T/HR Crushing Plant

Type

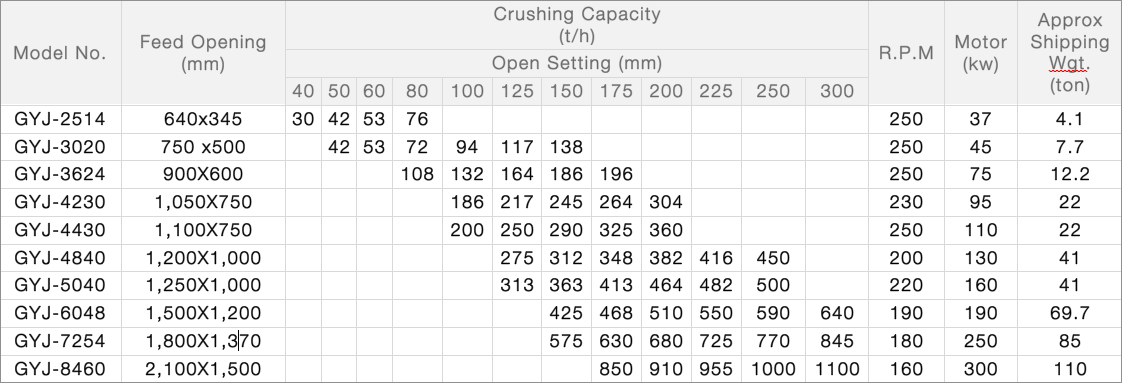

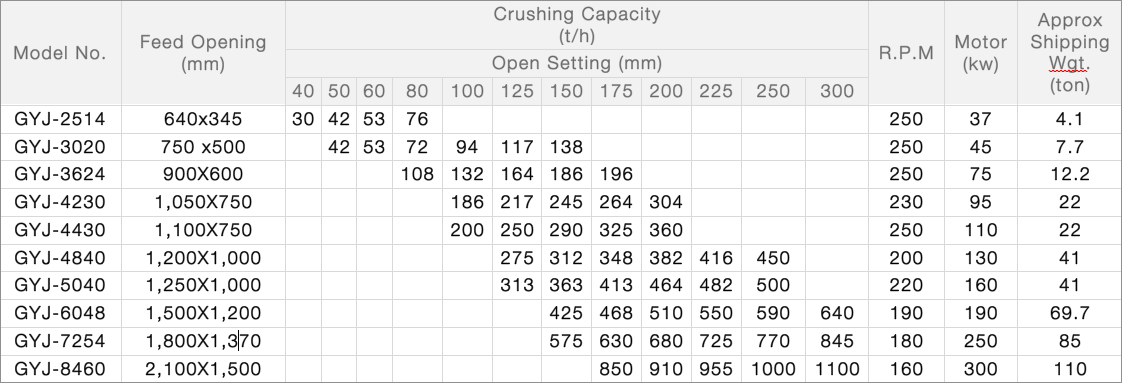

Jaw Crusher

Gilyoung SNC’s stationary Jaw crusher is widely used for primary crushers and secondary crushers for crushing all kinds of minerals and rocks.

It has a compact but strong and firm construction which offered trouble-free operation and easy maintenance.

The replacement component and jaw plate’s are composed of abrasion and strong durability material, be easily able to transportation and easily disassembly and assembly for easy field operation.

It has a compact but strong and firm construction which offered trouble-free operation and easy maintenance.

The replacement component and jaw plate’s are composed of abrasion and strong durability material, be easily able to transportation and easily disassembly and assembly for easy field operation.

● Increase production passing value and improve product

● The main frame structure and improve strength

● Quality improvement of component

● Adoption of the easy lubrication method

● Automation of aggregate outlet size control

● The main frame structure and improve strength

● Quality improvement of component

● Adoption of the easy lubrication method

● Automation of aggregate outlet size control

Feature of JAW CRUSHER

- ① Frame

- ② Fixed jaw plate

- ③ Swing jaw plate

- ④ Cheek plate bolt

- ⑤ Cheek plate

- ⑥ Protector

- ⑦ Main shaft

- ⑧ Bearing

- ⑨ Fly wheel

- ⑩ Swing jaw

- ⑪ Tension spring

- ⑫ Shim plate

- ⑬ Toggle block

- ⑭ Toggle plate

- ⑮ Tension rod

Cone Crusher

The Characteristic of MC Type Cone Crusher

1.Mutual compatible structure of Primary Cone & Secondary Cone type.

• Replacement of liner alone enables the conversion of the Primary Cone type and the Secondary Cone type.

• Change of use is very easy at the time of plant movement and increase.

2.Concave replacement mechanism.

• With the improvement of the liner assembly method, the concave replacement time is shortened.

• Maintenance is possible with the sleeve exchange at the site without welding.

3.Improvement of production volume for 16%

• Compared to same level of model, the production volume is increased for 16% or more.

• The crushing chamber structure is appropriate to optimal crushing mechanism

4.Hydraulics to open the crushing chamber.

• When the crushing chamber is clogged by the mantle in operation, the cleaning time is shorted.

• Replacement of liner alone enables the conversion of the Primary Cone type and the Secondary Cone type.

• Change of use is very easy at the time of plant movement and increase.

2.Concave replacement mechanism.

• With the improvement of the liner assembly method, the concave replacement time is shortened.

• Maintenance is possible with the sleeve exchange at the site without welding.

3.Improvement of production volume for 16%

• Compared to same level of model, the production volume is increased for 16% or more.

• The crushing chamber structure is appropriate to optimal crushing mechanism

4.Hydraulics to open the crushing chamber.

• When the crushing chamber is clogged by the mantle in operation, the cleaning time is shorted.

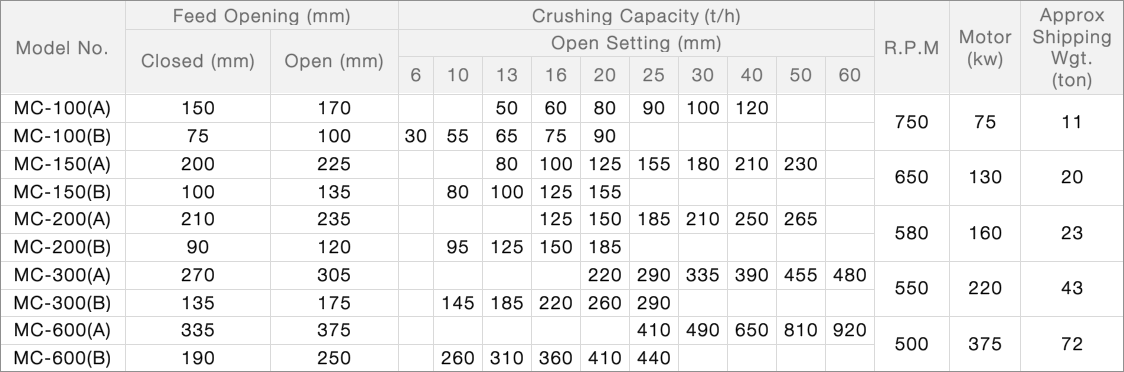

Specification for New MC Cone Crusher.

The Characteristic of CC Type Cone Crusher.

1.High crushing efficiency

High crushing efficiency with a strong shock compression crushing exercise.

2. Uniform Aggregate supply

Distributors are working on the upper main shaft is uniform aggregate supply.

3. Strong structure

Strong structure of powerful block type spring is able to uniform particle size distribution the correct crushing.

High crushing efficiency with a strong shock compression crushing exercise.

2. Uniform Aggregate supply

Distributors are working on the upper main shaft is uniform aggregate supply.

3. Strong structure

Strong structure of powerful block type spring is able to uniform particle size distribution the correct crushing.

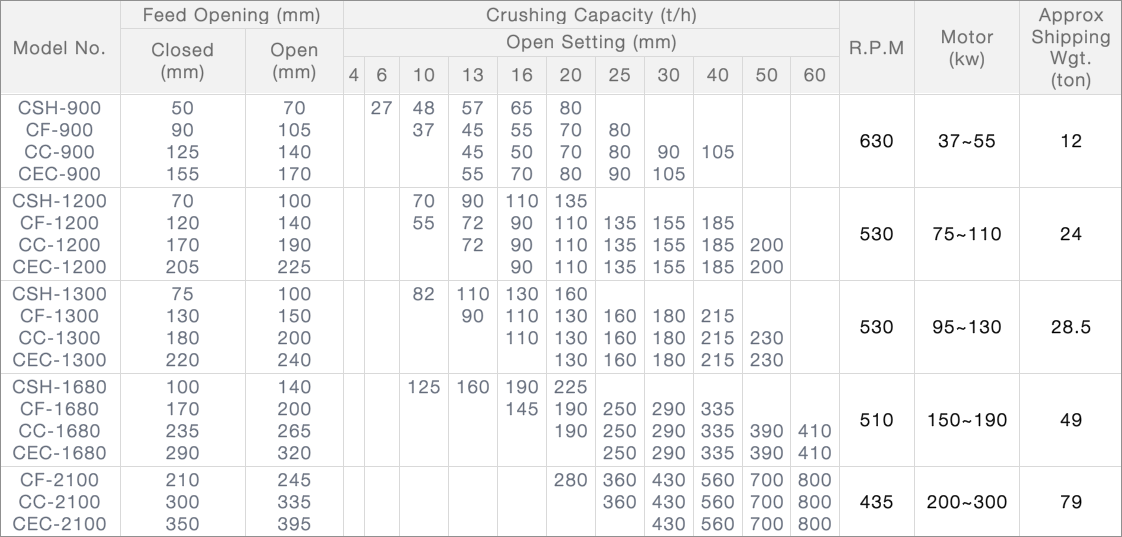

1. Specification for CC Type Cone Crusher.

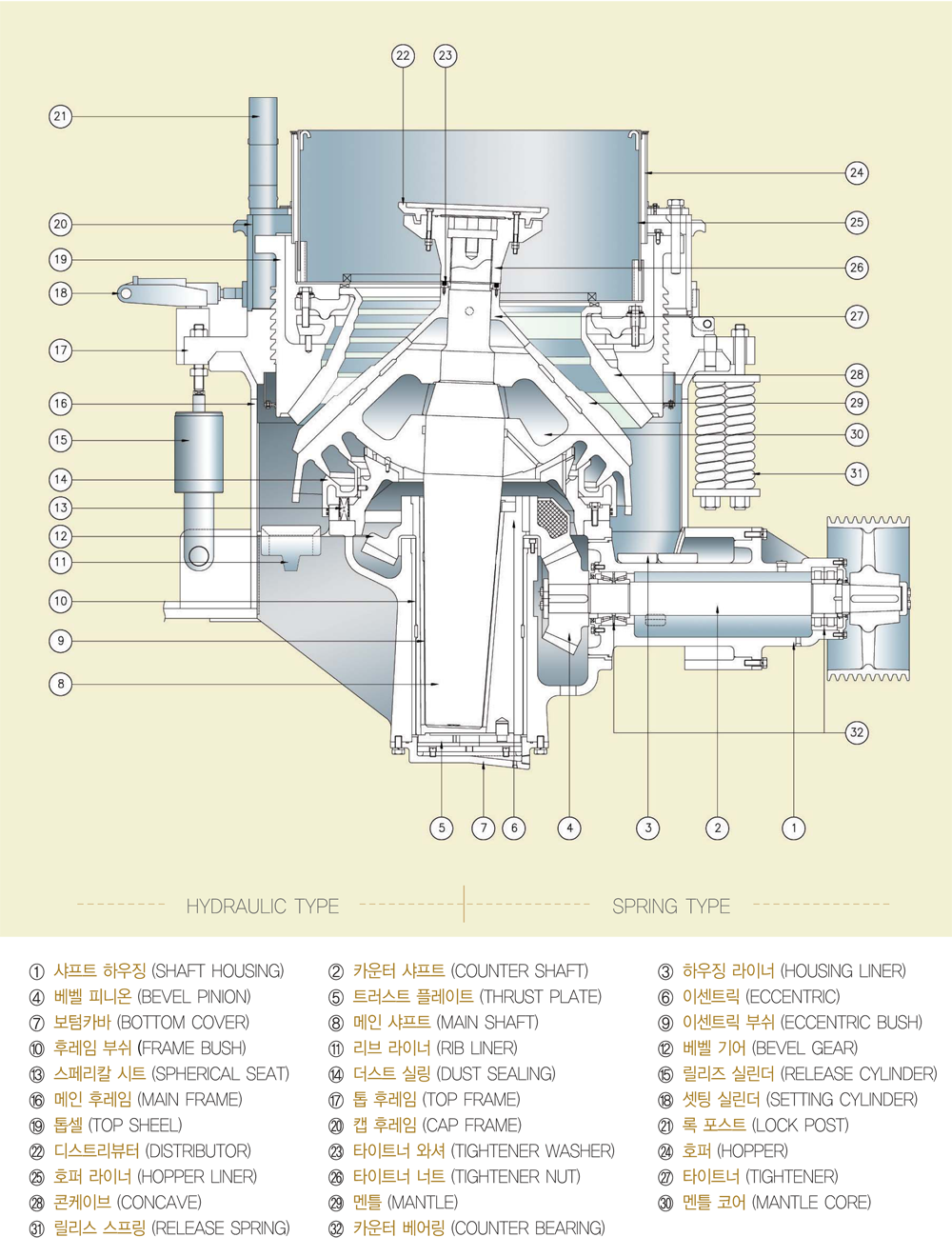

Construction of MC Type Cone Crusher.

Impact Crusher

수직형 임팩트 크러셔- 강력한 파쇄효과!!

1. 견고한 구조와 저소음, 저진동으로 설계되어 운전이 용이합니다.

2. 편석 및 각석을 둥글게 하여 자연사와 유사한 입형 구조로 생산을 할 수 있습니다.

3. 로터의 주속을 조정하여 원하는 파쇄비를 얻을 수 있고, 높은 생산능력과 안정적인 성능을 발휘 합니다.

2. 편석 및 각석을 둥글게 하여 자연사와 유사한 입형 구조로 생산을 할 수 있습니다.

3. 로터의 주속을 조정하여 원하는 파쇄비를 얻을 수 있고, 높은 생산능력과 안정적인 성능을 발휘 합니다.

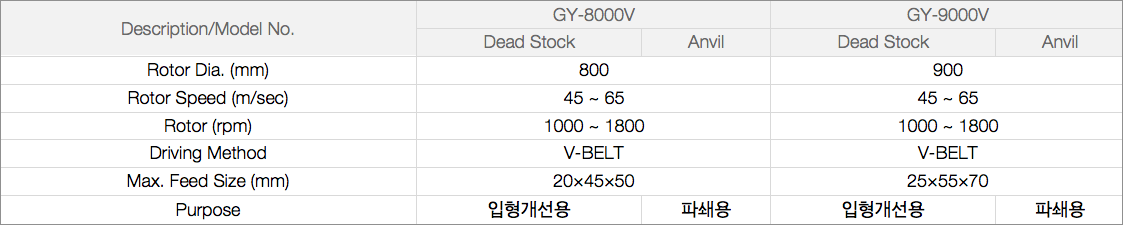

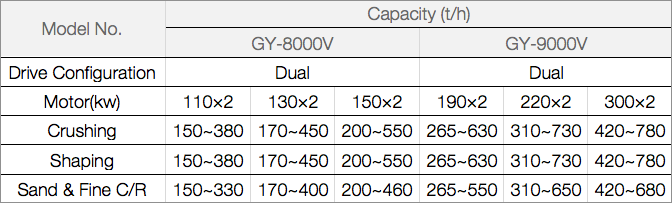

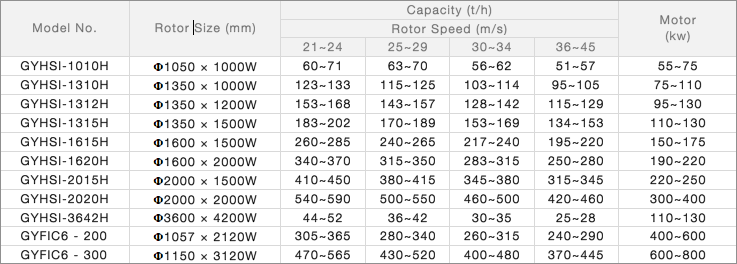

Specifications

Capacity

* 상기 능력은 겉보기 비중 1.6인 골재를 안정되게 공급했을 경우의 능력입니다.

* 처리 능력은 수분 또는 투입 원료에 따라 다소 차이가 납니다.

수평형 임팩트 크러셔 - 완벽한 편석 제거 및 해쇄!!

1. 파쇄비가 크며, 제품형상이 구형 또는 입방형으로 편석이 적습니다.

2. Impact Bar는 Boltless 취부 구조이며, 뒤집어 사용할 수 있어 사용효율이 매우 높습니다

2. Impact Bar는 Boltless 취부 구조이며, 뒤집어 사용할 수 있어 사용효율이 매우 높습니다

수평형 임팩트 크러셔 - 해머크러셔

주 사용 목적은 석탄, 맥석, 코크스, 슬래그, 사암, 석회암등 부서지기 쉬운 암석에 사용 됩니다.

안정적이고 높은 생산 능력과 저진동, 저소음 설계로 운전이 용이 합니다.

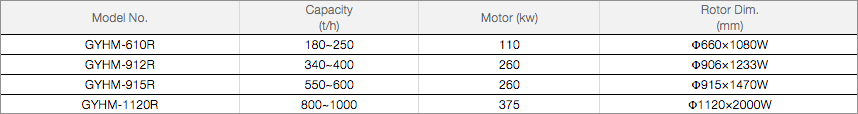

Ring Hammer Crusher Specification

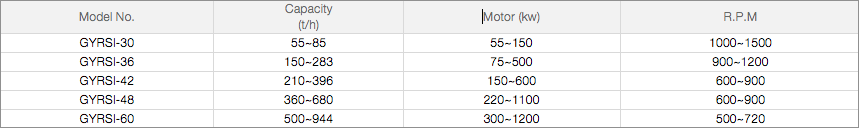

Reversible Impact Crusher Specification

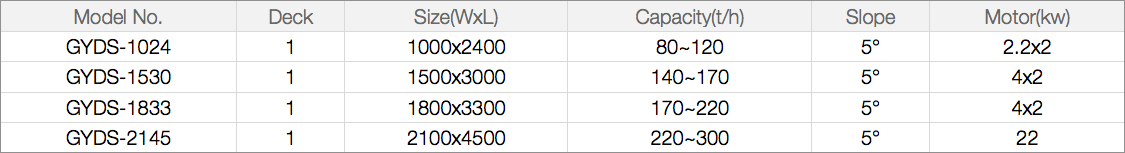

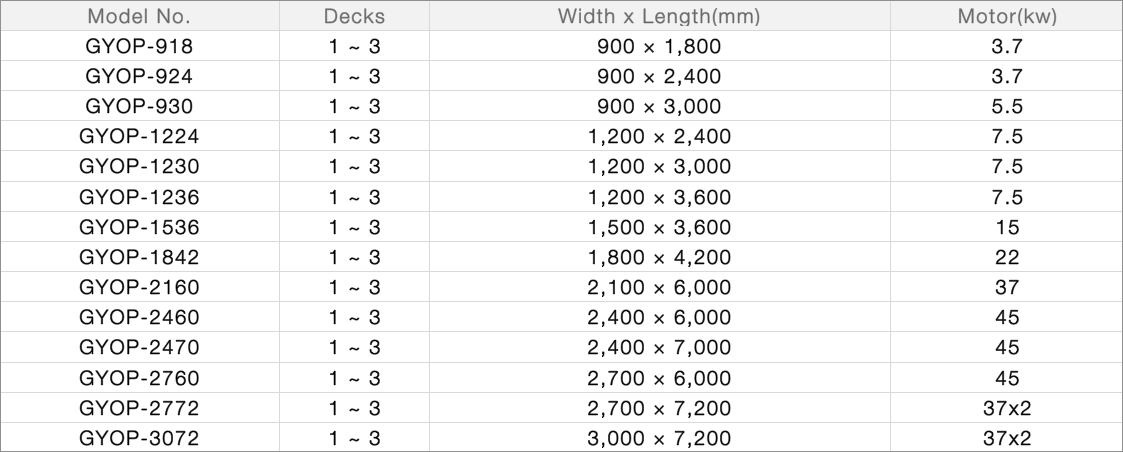

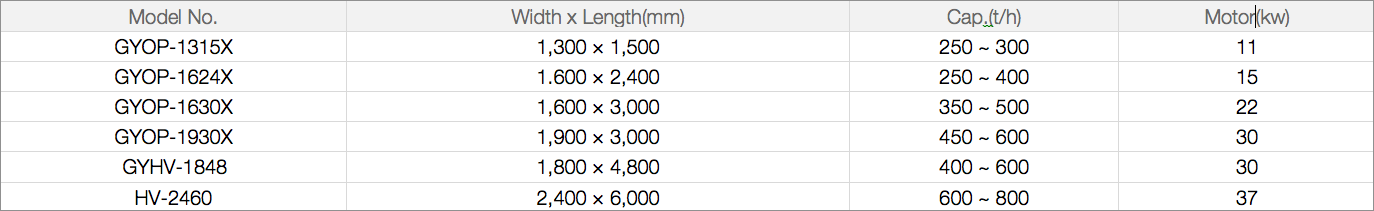

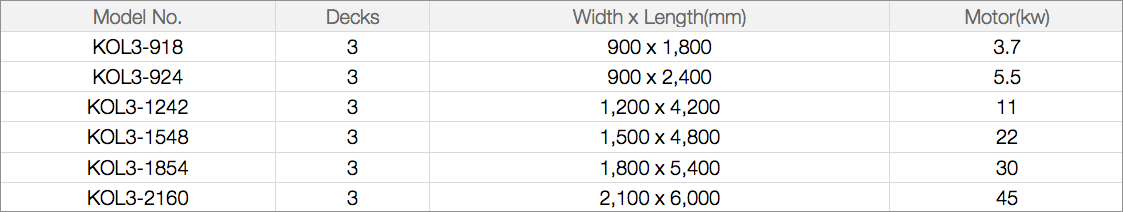

Vibrating Screen

경사형 스크린 (OP)

OP형 진동스크린은 구조가 아주 간단하고 운전이 매우 부드러우며, 강력한 진동으로 각단의

스크린망에서의 효과가 일정합니다. 낮은 부하나 높은 부하에서도 강하고 일정한 선별작용을

제공합니다.

흙제거 스크린

그리즈리-바의 간격이 다양하게 설계되어 원석이 1차 파쇄기로 투입되기 전에 표토(흙)제거는 물론

80mm이하 원석을 사전에 회수하여 1차 파쇄기의 효율을 극대화하기 용이한 설비입니다. 강력한 원

운동으로 중부하의 선별효과가 뛰어나며, 보다 깨끗한 원석을 파쇄기로 이송하는데 적합합니다.

Low head screens (Horizontal)

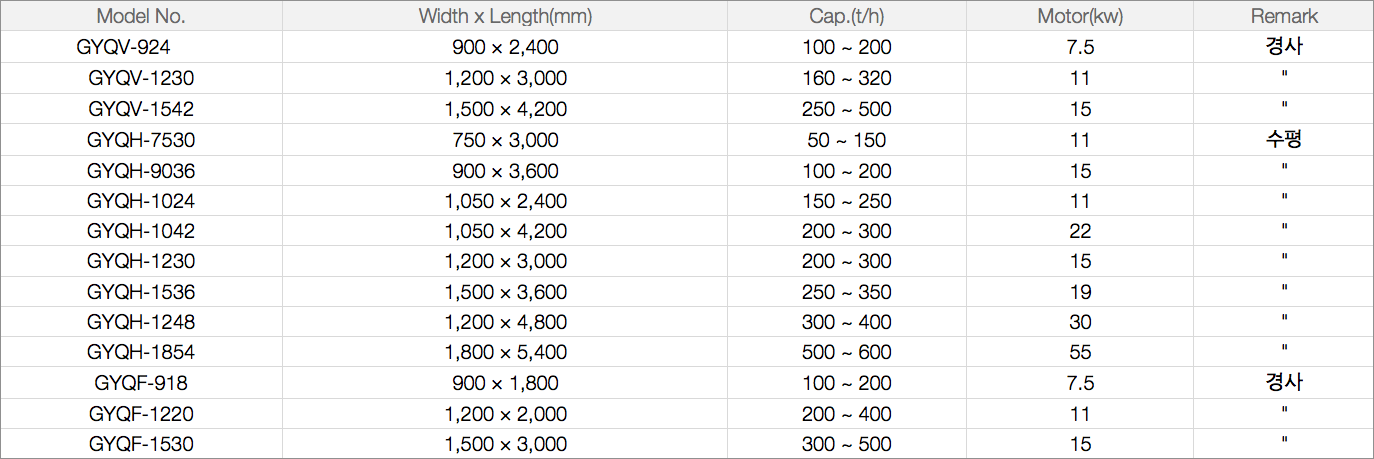

Feeder

Vibrating Grizzly feeder (QV, QH, QF)

QV-Vibrating Grizzly feeder delivers a smooth, and controlled flow of oversized materials to the primary crusher to perform at maximum capacity.

A heavy counter weight vibrating unit provides constant and powerful vibrating motion.

QH type is suitable for feeding with scalping of gravel or quarries.

Low headroom, quiet operation and accurate feeding are it’s big feature with easy controlling of speed and amplitude.

A heavy counter weight vibrating unit provides constant and powerful vibrating motion.

QH type is suitable for feeding with scalping of gravel or quarries.

Low headroom, quiet operation and accurate feeding are it’s big feature with easy controlling of speed and amplitude.

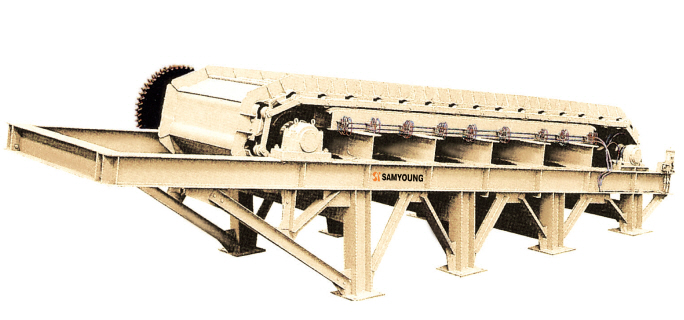

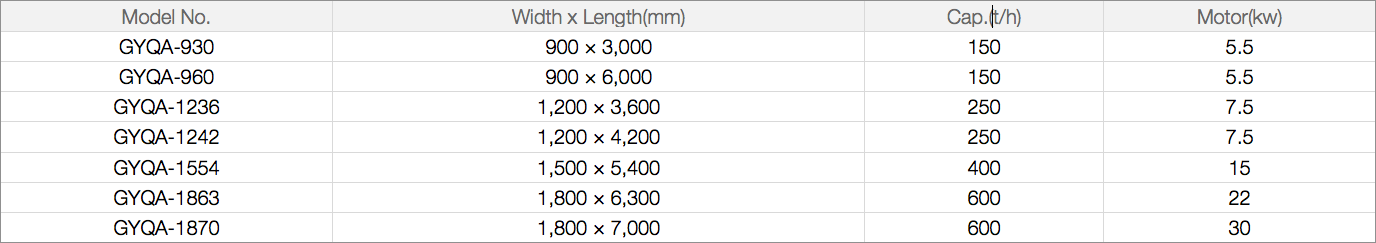

Apron feeder (QA)

Apron feeder is designed for mass amount transportation.

Particularly, it is suitable for transported a large quantities stones to the primary crusher.

It is possible to installed small area and easy control to aggregate feeding speed.

This machine is structure of strongly steel and has never given us any trouble.

It is widely used in metal mine, limestone mine, caldolomite dressing plant and stone crushing plant.

Apron Feeder (Q A) a rigid feeder with steel apron, particularly suitable for feeding ore to primary crusher, sizes range from 600 mm to 2,000mm to in apron width.

Particularly, it is suitable for transported a large quantities stones to the primary crusher.

It is possible to installed small area and easy control to aggregate feeding speed.

This machine is structure of strongly steel and has never given us any trouble.

It is widely used in metal mine, limestone mine, caldolomite dressing plant and stone crushing plant.

Apron Feeder (Q A) a rigid feeder with steel apron, particularly suitable for feeding ore to primary crusher, sizes range from 600 mm to 2,000mm to in apron width.

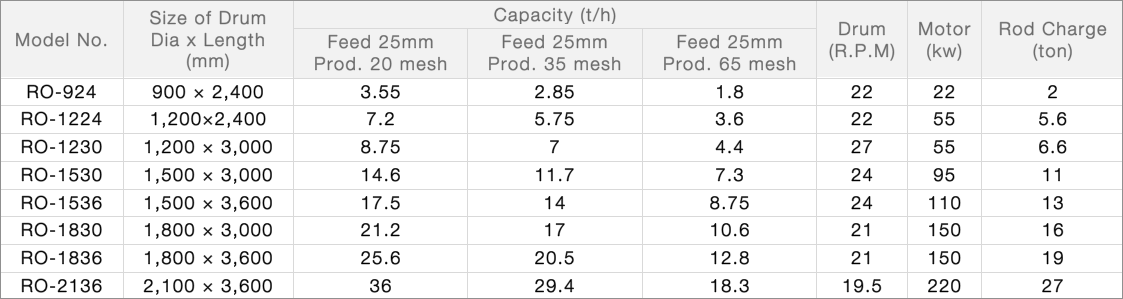

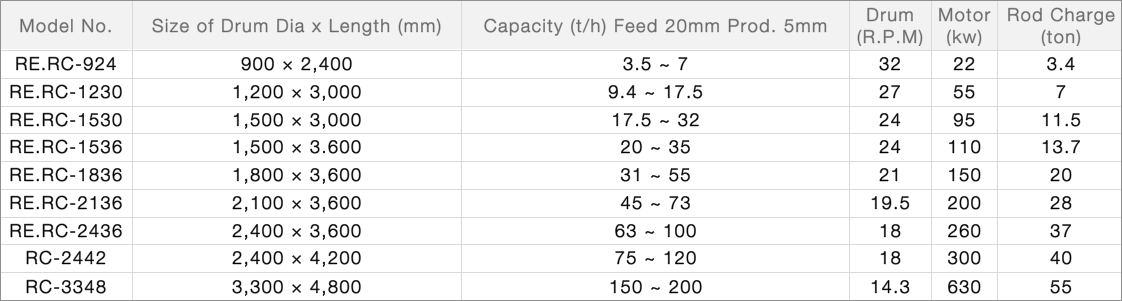

Road Mill

Rod mill is the key equipment for grinding after materials are crushed at crushing plant. Rod mill is an efficient crushing machine for grinding various materials into powder. Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills. Rod mills crush generally coarser than those produced in Ball mill, and rod mills are well suited to handle coarser feed and to control the bigger size of the product. Rod mill has Type RO, RE and RC depending on different purposes. Rod mills are widely applied in cement industry, chemical industry, new building materials, fire resistant materials, fertifizer, porcelain and glass industry etc.

Rod Mill Working principle

Rod mill runs along the side gear. Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices, Steel rods of different specifications are installed in the crushing chamber. When the frame rotates, centrifugal force is produced. At the same time, the steel rods are carried to some height and then fall to grind and strike the material. After grinded in the crushing chamber, the powder is discharges by output material board.

Rod Mill Features and Benefits

Rod mill is made up of feeding part. discharging part. gyre part. transmission part (reducer, small transmission gear, motor, and electrical controller)

Rod Mill Working principle

Rod mill runs along the side gear. Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices, Steel rods of different specifications are installed in the crushing chamber. When the frame rotates, centrifugal force is produced. At the same time, the steel rods are carried to some height and then fall to grind and strike the material. After grinded in the crushing chamber, the powder is discharges by output material board.

Rod Mill Features and Benefits

Rod mill is made up of feeding part. discharging part. gyre part. transmission part (reducer, small transmission gear, motor, and electrical controller)

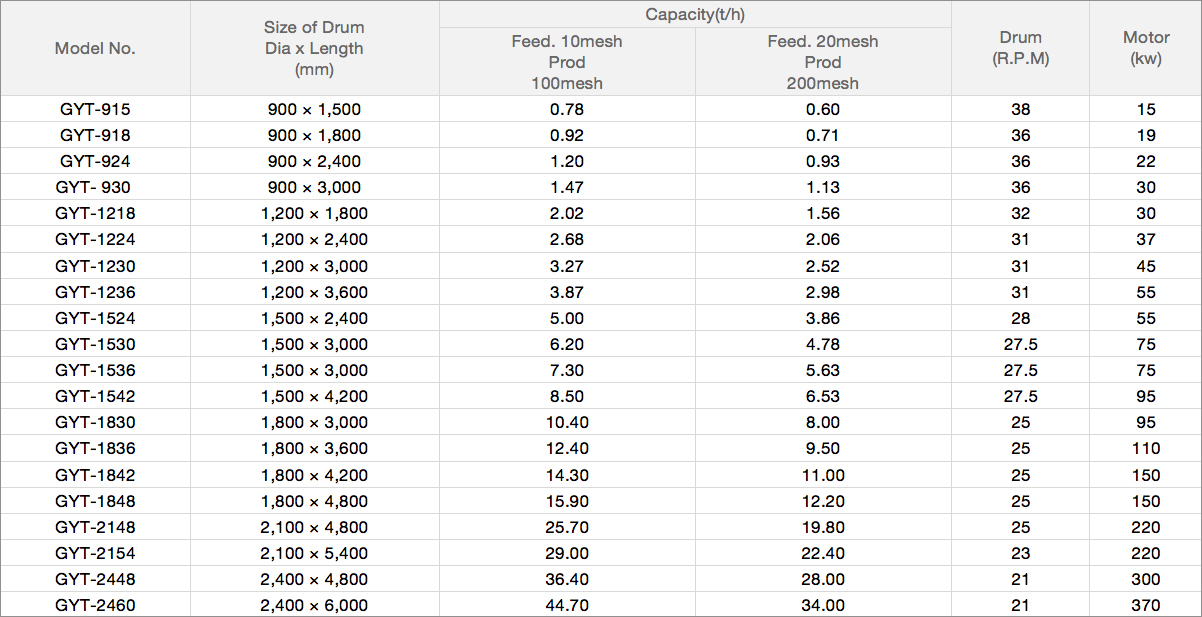

Specification for Rod Mill (RO)

Specification for Rod Mill (RE, RC)

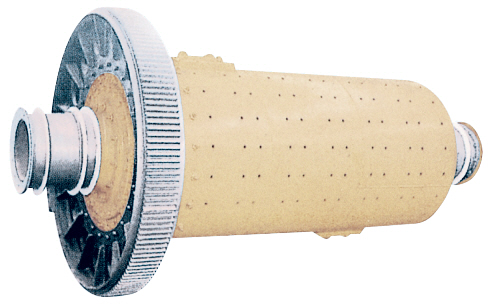

Ball Mill

Type T Tube Ball Mill specification

Balll mill is the key equipment for grinding after materials are crushed at crushing plant.

Ball mill is an efficient crushing machine for grinding various materials into powder

Ball mills are grinding machine which employ high carbon steel or special steel balls in ball mills. Ball Mill Crushes generally finer than those produced in rod mill and rod milts are well suited to handle finer feed and to control the smaller size of the product.

Tube type(Type T) Ball mill can grind materials to a fineness of minus 200mesh and is used as a secondary grinding milt after the Conical type(Type C) or Grate type(Type G) Ball mill.

Type T Ball mills are to produce a finished product from relatively fine feed in an open or closed circuit. These ball mlHs are equipp얹 with thinner shelf liners and employ smaller size grinding balls than that of Type C Ball mill

Ball Mill is widely open in cement industry, chemical Industry, new building materials, fire~reststont materials, fertilizer,porcelain and glass industry, ete.

Ball Mill Working principle

Ball mill runs along the outside gear, Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices. Steel rods of different specifications are installed in the crushing chamber. When the frame rotates, centrifugal fare is produced. At the same time, the steel rods are carried to some height and then fall to grind and strike the material. After grinded in the crushing chamber, the powder is discharges by output material board.

Ball Mill Features and Benefits

Ball mill is made up of feeding part, discharging part, gyre part, transmission part (reducer,small transmission gear, motor, and electrical controller) and so on

Ball mill adopts a steel cast hollow axis and the linings can be replaced

Ball milt adopts a forged rotary gear.

Ball mill has crushing chamber with wearable plates.

Ball mill runs steadily and efficiently.

Classifier

Sand classifier

Cleaning, classification, sludge dewatering - 3 at a same time,

Processing the sand is washed and dewatered sludge, and at the same time, the classifying equipment.

High mesh classifier dewatering screen and a cyclone is consists of one unit .

Sludge classified as 2 steps. (Step 1 - HM Classifier, spep two - Cyclone classification)

removing the only sludge than 200mesh you can produce the perfect quality of sand.

Processing the sand is washed and dewatered sludge, and at the same time, the classifying equipment.

High mesh classifier dewatering screen and a cyclone is consists of one unit .

Sludge classified as 2 steps. (Step 1 - HM Classifier, spep two - Cyclone classification)

removing the only sludge than 200mesh you can produce the perfect quality of sand.

Classifier

Certain effect of classifying until 200mesh.

High classification efficiency possible to the sand production for high strength concrete.

You can adjust the # 100 to # to 200mesh for classifying points in quantity adjustment

High classification efficiency possible to the sand production for high strength concrete.

You can adjust the # 100 to # to 200mesh for classifying points in quantity adjustment

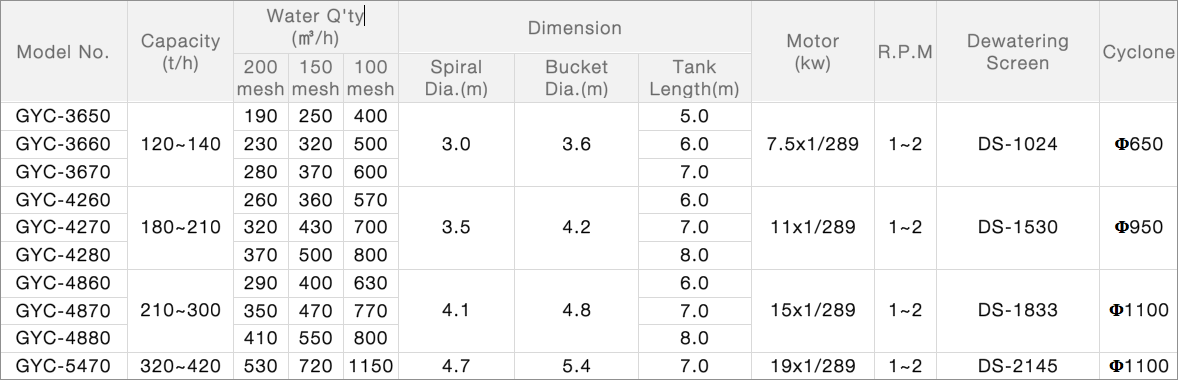

High Mesh Classifier & Cyclone Specification

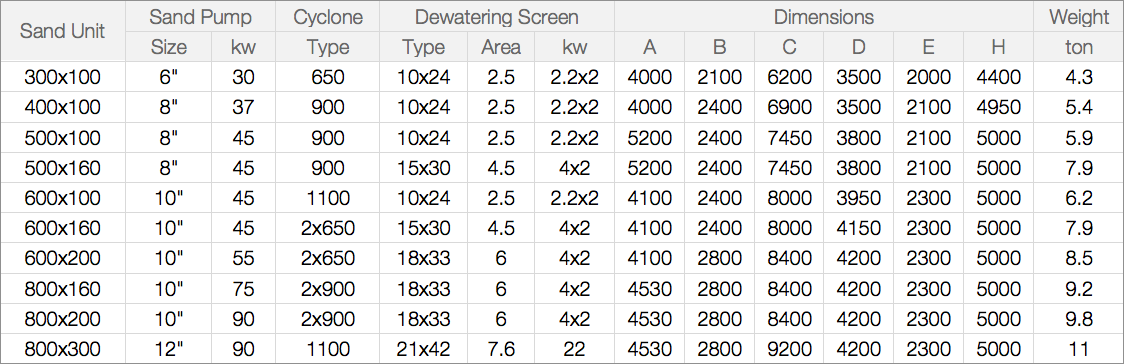

Sand Unit

Sand Unit

1. Sand unit of Gilyoung SNC has high efficiency of classification.

2. Sand unit for Crushing Plant is convenience of installment at the small space.

3. High efficiency of dewatering using sand unit

2. Sand unit for Crushing Plant is convenience of installment at the small space.

3. High efficiency of dewatering using sand unit

The best dewatering efficiency

1. Getting the best efficiency to use after production immediately

2. Polyurethane meshes are used and can be available to exchange partly in case of wearing of them

3. As an attached of vibrating motor,the strong vibration occurs Simultaneously available to adjust amplitude of vibration according to physical properties of sand

2. Polyurethane meshes are used and can be available to exchange partly in case of wearing of them

3. As an attached of vibrating motor,the strong vibration occurs Simultaneously available to adjust amplitude of vibration according to physical properties of sand