Modified Asphalt : Modifica Asphalt

Overview

Globally used a modified asphalt and additives in asphalt concrete are already more than 50 years. But this ten years begin to new attention from the paving market.Recently in Korea using a variety of modifiers and additives the reason is as follows.

● Increased demand for asphalt pavement.

● The causes of the plastic deformation of asphalt paving, the traffic, traffic load and increase the tire pressure a lot.

● There is pressure from the environmental and economic, as additive in asphalt mixtures to dispose of waste and industrial by-products are put on it. (such as tires, roof materials, glass, sulfur and ashes).

● In the public institution, the first pavement cost is more expensive more than general pavement of road, but increasing the length of public life and reduce the early damage.

All asphalt concrete mixtures need not the modified asphalt.

For the mixing of asphalt concrete using an additive or a modified asphalt, the special technical reasons is as below.

- Can be obtained a more solid mixture at a high temperature in order to suppress the plastic deformation of the public.

- Improve the fatigue resistance of asphalt mixtures.

- Improve the adhesion of asphalt and aggregate in order to reduce the moisture sensitivity peeling.

- Improve the abrasion resistance of the mixture to reduce to falling off.

- Minimize the construction of a light mixture (tender mix) problem.

- Play the aging of asphalt binder.

- Allow thicker coating of the aggregate to asphalt to increase the durability of the mixture.

- Reducing the flushing or bleeding.

- Improved resistance to aging or oxidation.

- Reducing the thickness of the pavement.

- Reduced life-cycle costs of asphalt paving (life cycle cost)

- Improve overall commonality of asphalt pavement.

Commonly, in Europe's asphalt modification material is used more than United States.

In Europe, the Contractor may required the guarantee of few years for the commonality of the asphalt mixture. By the reason, it is to promoted the use of modified asphalt material, for the obtain a reduction in the life-cycle cost and secure a commonality.

Classification

Modified Asphalt is ?

Gilyoung Modified Asphalt is the vulnerability of ordinary asphalt by improving the sensitivity to temperature.

The product is modified asphalt. In addition asphalt with improve quality asphalt is for the increasing of the resistance to deformation at high temperatures (plastic deformation) and resistance to cracking at low temperatures.

The product is modified asphalt. In addition asphalt with improve quality asphalt is for the increasing of the resistance to deformation at high temperatures (plastic deformation) and resistance to cracking at low temperatures.

Why used modified asphalt.

- For an increase in such traffic, traffic load, tire pressure promote resistance to plastic deformation of the asphalt paved road

- Fatigue cracking resistance and ensure wetting

- Ensure commonality of asphalt pavement in extreme temperature changes

- Increased public life cycle time of paved road and reduce maintenance costs

- Fatigue cracking resistance and ensure wetting

- Ensure commonality of asphalt pavement in extreme temperature changes

- Increased public life cycle time of paved road and reduce maintenance costs

Modified Asphalt Classification

Asphalt concrete is comprised of aggregate and asphalt.

Almost expression of the property appears by the composition and mix of aggregate particle size will serve to support the structure of the asphalt mixture.

However, the configuration of the aggregate mixture is In theory, practically through the study design of the aggregate content and particle size of 100% are possible. The temperature of the asphalt mix to be sensitive to the issue.

It has a sensitive nature, depending on the temperature of asphalt, at 60 degrees to that plastic deformation starts by default (package internal temperatures (around 07), summer) and have the properties of the asphalt is soft is expressed, at low temperatures (around 0 °) got a brittle and caused to the damaged of the asphalt crack phenomenon.

Almost expression of the property appears by the composition and mix of aggregate particle size will serve to support the structure of the asphalt mixture.

However, the configuration of the aggregate mixture is In theory, practically through the study design of the aggregate content and particle size of 100% are possible. The temperature of the asphalt mix to be sensitive to the issue.

It has a sensitive nature, depending on the temperature of asphalt, at 60 degrees to that plastic deformation starts by default (package internal temperatures (around 07), summer) and have the properties of the asphalt is soft is expressed, at low temperatures (around 0 °) got a brittle and caused to the damaged of the asphalt crack phenomenon.

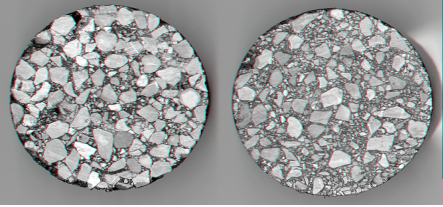

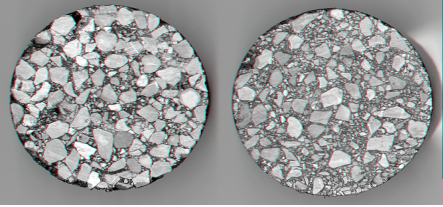

1. Improving the Aggregate of modified asphalt concrete

Typical products SMA mixtures are to improve the performance of the asphalt mixture by modifying the aggregate,

To rework the for flat or elongated particles in coarse aggregate and produced down the flat or elongated particles in coarse aggregate.

SMA as to increase the bonding strength between the aggregate mixture is main object contains an aggregate (for example, 13mm, 10mm) grain size number of stages of the content, There is a lot of surface pores because of this.

Properties of the mixture is not a factor that inhibits the surface pores of the SMA mixture,

Than normal asphalt and fiber additives are added to the mixture inside the cavity and it’s blocked by the high asphalt content.

Furthermore, surface pores of the SMA has the effect is reduce of the noise during the passing the vehicle.

Typical products SMA mixtures are to improve the performance of the asphalt mixture by modifying the aggregate,

To rework the for flat or elongated particles in coarse aggregate and produced down the flat or elongated particles in coarse aggregate.

SMA as to increase the bonding strength between the aggregate mixture is main object contains an aggregate (for example, 13mm, 10mm) grain size number of stages of the content, There is a lot of surface pores because of this.

Properties of the mixture is not a factor that inhibits the surface pores of the SMA mixture,

Than normal asphalt and fiber additives are added to the mixture inside the cavity and it’s blocked by the high asphalt content.

Furthermore, surface pores of the SMA has the effect is reduce of the noise during the passing the vehicle.

2. Improving the asphalt of modified asphalt concrete

The products of the modified asphalt is have a varies type of the asphalt.

It is the basic idea is to suppress in the form minimizing for temperature effects of a road damaged commonly found background of plastic deformation and crack.

There are several different types of modifiers, used such as plastic, rubber, oxidizing agents.

Among the materials used for the oxidizing agent is as if to increase the strength by oxidation to force the asphalt.

Since the result in reducing the durability of the paving.

We recommend that you refrain from using such as SBS, CRM, PBSC, ecopalt is a typical example a comparison of the normal asphalt modified asphalt below.

※ A comparison of the normal asphalt and modified asphalt.

※ Modified Asphalt Division

The products of the modified asphalt is have a varies type of the asphalt.

It is the basic idea is to suppress in the form minimizing for temperature effects of a road damaged commonly found background of plastic deformation and crack.

There are several different types of modifiers, used such as plastic, rubber, oxidizing agents.

Among the materials used for the oxidizing agent is as if to increase the strength by oxidation to force the asphalt.

Since the result in reducing the durability of the paving.

We recommend that you refrain from using such as SBS, CRM, PBSC, ecopalt is a typical example a comparison of the normal asphalt modified asphalt below.

※ A comparison of the normal asphalt and modified asphalt.

| General Asphalt (AP-3, AP-5) | Modified Asphalt | |

|---|---|---|

| Standard | Penetration standard (empirical) | PG standard (materials engineering) |

| Distinct | criteria of division (High and low temperature properties not measured) | Management based on Plastic deformation, fatigue and low temperature cracking and directly related to the quality items (High and low temperature properties not measured) |

| Characteristics | As products are produced at oil refinery there is a limit to improve the quality - Change the physical properties to be sensitive to the temperature change | Production of various specifications PG rating - The physical properties change with temperature is less - Excellent resistance to plastic deformation and crack - Elastic restoring force increases due to the vibration of the bridge, the deflection Resistant to cracking. - A pre-mixing system as in the normal asphalt Can be used. |

※ Modified Asphalt Division

| Division | Characteristic |

|---|---|

| Camcrete | Dissolved metal component organic compounds |

| Superphalt | SBS composite polymer |

| SBR Latex | SBS composite polymer |

| Gilsonite | Containing nitrogen enriched material |

| EVA | plastic type |

| SMA | natural fiber |

| CRM | rubber-modified asphalt (waste tyre) |

3. Improving the asphalt and aggregate of modified asphalt concrete

The above-mentioned with a modified aggregate and asphalt products PSMA is only.

The above-mentioned with a modified aggregate and asphalt products PSMA is only.

Products of Gilyoung SNC

MODI-PHALT

The road asphalt concrete pavement material is a commonality standard PG 64-22 grade asphalt and use a lot in common road paving.

Sensitive to the temperature of asphalt concrete is effected because of the traffic load of asphalt ductility at temperatures of 60-80 degrees.

Among the asphalt concrete road traffic load is heavy traffic in many areas in the summer the temperature rises to 80 degrees pavement layer environment plastic deformation of the package will frequently happen.

In addition, the rise in average temperatures worldwide climate pavement road is changing more and more poorly.

A binder in asphalt concrete at this point of the road package it is eliminated that the sensitivity to temperature of the asphalt is very important.

ROADSEALER

There are several maintenance issues are occurring after construction of asphalt concrete paved road.

For example, the most common plastic deformation, cracks, porthole this problem are generated.

This maintenance material is product for the repair cracks and crevices.

This is used for the initial crack of after the initial traffic opening of asphalt concrete pavement and superannuated of already constructed pavement road.

Damage type of Asphalt Pavement

* In the first : Means 1 to 3 years after construction, plastic deformation, be pressed, old road, cracks due to road subsidence or deformation of floating.

* Latterly : fatigue crack, temperature cracking, wear, labeling etc, due to aging damage, desorption and cracks.

* In the first : Means 1 to 3 years after construction, plastic deformation, be pressed, old road, cracks due to road subsidence or deformation of floating.

* Latterly : fatigue crack, temperature cracking, wear, labeling etc, due to aging damage, desorption and cracks.

The type of road-cracks.

Cracking

Cracking is occure the various causes, stress by axial load, temperature change, moisture of underground, including temperature change.

Cold cracking

Also known as crack such as turtle's back. If receive a stress to fatigue persists, be cause by overloaded vehicle, this is caused by improper paving thickness.

Also during the maintenance to determine the cause expected traffic load research, groundwater investigation, stabilization of a weak stratum, need a thick enough overlay pavement.

Generally it occurs at equal intervals at right angles from the center line of the road.

These transverse cracks are according to the temperature in excess of the tensile strength of the asphalt mixture sufficient enough to induce shrinkage stress occurs when the surface temperature drops.

While the repairing of road, must be use the asphalt mixture of with a lower viscosity at low temperatures.

Also during the maintenance to determine the cause expected traffic load research, groundwater investigation, stabilization of a weak stratum, need a thick enough overlay pavement.

Generally it occurs at equal intervals at right angles from the center line of the road.

These transverse cracks are according to the temperature in excess of the tensile strength of the asphalt mixture sufficient enough to induce shrinkage stress occurs when the surface temperature drops.

While the repairing of road, must be use the asphalt mixture of with a lower viscosity at low temperatures.

Longitudinal cracking

It cracks occur in parallel with the center line of the road. Occurs often in the next paved road or between the trace of wheels end joints, permeate water into the cracks and crevices larger cracks and accelerates the damage of the paved road.

It is possible to repair by sealing in the early stages.

It is possible to repair by sealing in the early stages.

Block cracking

This cracking is the same as the low-temperature cracking. Almost rectangular with cracks in the longitudinal direction and the transverse direction it often occurs in low traffic roads.

This crack is occurs when stored long time in silos and asphalt concrete mixed a long time or mixed high temperature.

This crack is occurs when stored long time in silos and asphalt concrete mixed a long time or mixed high temperature.

Road Sealer

Gilyoung SNC's Road Sealer was developed in order to repair the above-mentioned cracking products.

Prepared by the addition of asphalt, rubber modifiers, additives, product.

The product is used dissolving by heat on the construction site.

Gilyoung SNC's Road Sealer was developed in order to repair the above-mentioned cracking products.

Prepared by the addition of asphalt, rubber modifiers, additives, product.

The product is used dissolving by heat on the construction site.